Deployable 3D Printing

Deliver your additive manufacturing straight to your area of operation, realising many logistical advantages.

Additive manufacturing, where you need it.

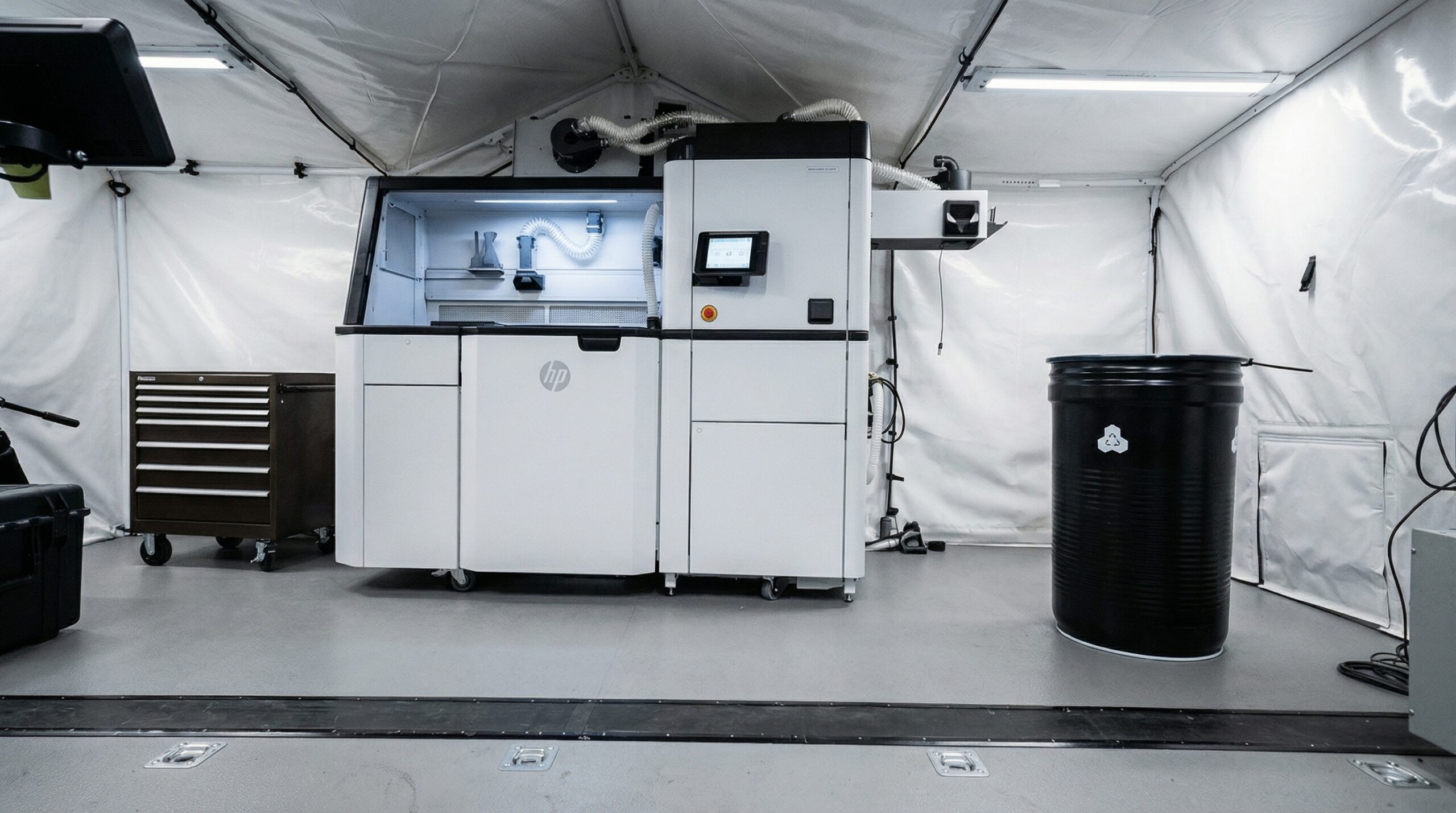

Additive manufacturing and 3D printing are increasingly critical in both military and commercial applications. Traditional systems are designed for fixed labs and controlled environments, not for field deployment. Our expanding container systems provide clean air, environmentally regulated spaces that can be deployed worldwide. These shelters make it possible to bring advanced manufacturing capabilities directly to remote or operational locations, giving organizations immediate access to production resources wherever they are needed most.

Our expandable shelters arrive fully equipped with electrical, lighting, HVAC, and furniture integration. Purpose-built containerised systems such as EHMECC, MECC, and TRECC are manufactured in our facilities, ensuring precise quality and flexibility. This allows us to collaborate with your engineers to design and deliver deployable additive manufacturing facilities tailored to your exact requirements. Whether you need specialised integration or unique layouts, we provide solutions that match your mission, production, and operational objectives efficiently.

Modular design enables scalable facilities and flexible connected operations

Each shelter is designed with common interfaces, allowing seamless connection to other units. Your additive manufacturing system can be linked to workshops, offices, storage, or even soft shelters, enabling integrated facility layouts. This modular approach supports scalability, so your operation can expand as requirements evolve. By connecting systems together, you create an adaptive, mission-ready environment that grows with your production needs and operational scale, ensuring long-term efficiency and optimised deployment wherever required.

Mobile systems deliver manufacturing capability to diverse operational environments

Our fully integrated shelters, such as TRECC, are engineered for high mobility. They can be transported on trailers or mounted directly onto vehicles. The design includes a roof that expands vertically during deployment, maintaining a low profile during transit. This ensures better vehicle performance by keeping weight distribution balanced and overall height reduced. Once on location, the shelter expands to create a full workspace, providing immediate access to additive manufacturing wherever operations demand deployment.

Rapid deployment ensures operations are production-ready within minutes

Our shelters operate using vehicle power, onboard generators, or connection to the local grid. This allows additive manufacturing systems to begin producing within minutes of arrival at a site. The combination of mobility, integrated infrastructure, and power flexibility ensures minimal setup time. Whether deployed in remote areas or near established infrastructure, our systems deliver production capability fast, helping organisations stay agile, reduce downtime, and manufacture critical parts exactly where and when required.

Specialised shelters deliver precise power and HVAC for production quality

Additive manufacturing often requires tightly controlled HVAC and specific power configurations to meet certification standards. Maintaining exact conditions is essential for producing reliable, high-quality components. Our shelters are built to support manufacturer-recommended environmental and electrical requirements, ensuring compliance and performance. By tailoring infrastructure to your systems’ needs, we provide a stable, dependable environment for consistent results. This capability ensures that deployed operations can maintain the same standards as fixed, laboratory-based production facilities anywhere.

Secure transport packing enables fast transition from shipment to production

During transit, all equipment required for additive manufacturing is safely packed within the shelter’s core. This ensures secure transport by air, sea, rail, or road without risk of damage. Upon arrival, the equipment is quickly moved into position for use, minimising downtime. By integrating both transport and deployment into the shelter design, we provide a streamlined system that transitions smoothly from packed transport mode into a fully functional production environment within minutes.

Complexed shelter networks deliver complete operational facilities with ease

Shelters can be interconnected to create large, complex facilities in the field. These networks can include additive manufacturing, workshops, material storage, offices, and waste management—all configured to suit operational needs. This ability to complex shelters expands your capabilities significantly, allowing you to replicate a complete base infrastructure almost anywhere. Our deployable solutions ensure large-scale facilities are easy to establish, flexible to configure, and effective in meeting demanding mission and production requirements.

Early customisation enables bespoke additive manufacturing shelter design

We can collaborate with you from the earliest stages, even during construction of the core MECC frame. This allows bespoke requirements and unique features to be built into the shelter from the ground up, ensuring your additive manufacturing facility meets exact specifications. By integrating design and engineering early, we deliver tailored solutions that maximize efficiency and capability. The result is a deployable manufacturing system that truly aligns with your operational and production needs.

Related Products

Weatherhaven is committed to delivering shelter and camp solutions that work for you.

We have a team of technical staff who will work with you; whether it’s a straight forward product purchase, or a complex shelter systems requirement. Our breadth of knowledge in delivering real world solutions is second to none, so please reach out and let us help.

Related

insights

Please get in touch if you would like to know more about our Military or Commercial shelter and camp solutions.