Weatherhaven delivered a pioneering forward-deployable additive manufacturing facility to a US client, demonstrating true innovation in rapid fielded capability. Using our MECC units, this system delivers cost-effective, adaptable, and robust 3D printing at the front line. Uniquely, it provides fully operational facilities that can deploy, complex, and operate seamlessly on the ground or directly from trucks. The result is an agile solution, giving military and expeditionary operators immediate access to advanced manufacturing in contested or remote locations.

This breakthrough facility consists of two MECC units—one as a workshop and one as a dedicated additive manufacturing facility. They are complexed through an innovative interface, enabling fast setup and operational flexibility. Crucially, the MECC expandable containers maintain functionality in diverse configurations: standalone on the ground or mounted on vehicles. This modular design maximizes capability while minimizing logistical burden, setting a new benchmark for rapidly deployable containerised additive manufacturing.

Integrated workshops and additive systems deliver instant deployable capability

Each expandable MECC unit is delivered fully integrated with all the systems and interfaces, ready of rate client to ‘drop in’ their printer technology. Unlike traditional deployments that require time-consuming setup, this system achieves full operational capability within minutes of arrival. The ability to transition from transport mode to production-ready is a game-changing feature, allowing immediate response to mission requirements. This level of integration ensures the end user has a complete, ready-to-operate manufacturing capability, anywhere in the world.

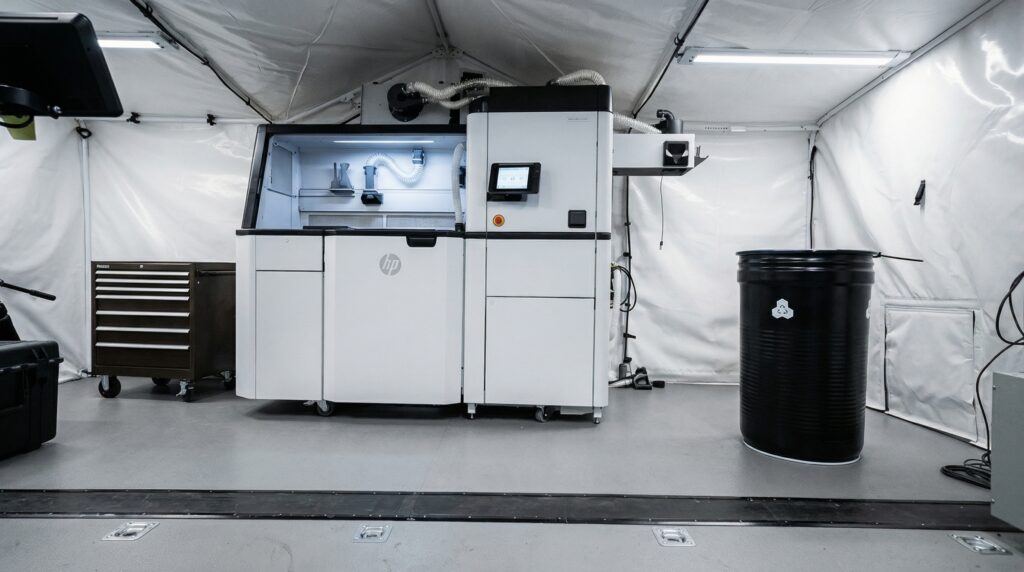

Powerful HVAC ensures controlled clean-air environment for additive processes

Critical to additive manufacturing success is a stable, clean, and controlled environment. The MECC facility incorporates a powerful HVAC system, ensuring the workspace maintains stringent environmental standards. This not only protects sensitive printing equipment but also ensures personnel comfort and safety during operations. By guaranteeing optimal conditions regardless of external climate, the facility can function across the globe. It provides true global capability, ensuring additive processes run with uncompromising precision.

Global transportability proven with CSC certification and C-130 compliance

Rapid deployment demands logistics flexibility, and these MECC units deliver exactly that. Each is CSC certified to transport as a standard 20′ ISO container, ensuring easy movement via sea, rail, or truck. Moreover, they are specifically engineered to meet C-130 airlift requirements, including reduced 8′ height profiles. By designing and manufacturing in-house, Weatherhaven can tailor MECC specifications to unique mission needs. This versatility ensures rapid delivery of manufacturing capability to any global theater.

Expandable MECC offers unmatched deployed volume and environmental protection

The MECC’s advanced layered fabric wall system creates a perfectly sealed environment, protecting equipment during both transport and deployment. Once expanded, the three-in-one container offers unrivalled usable volume, giving operators the space to house sensitive additive systems while maintaining full environmental protection. This capability ensures the most delicate manufacturing processes remain unaffected by dust, temperature swings, or other external conditions. Operators gain the benefits of a large, stable facility without sacrificing transportability or protection.

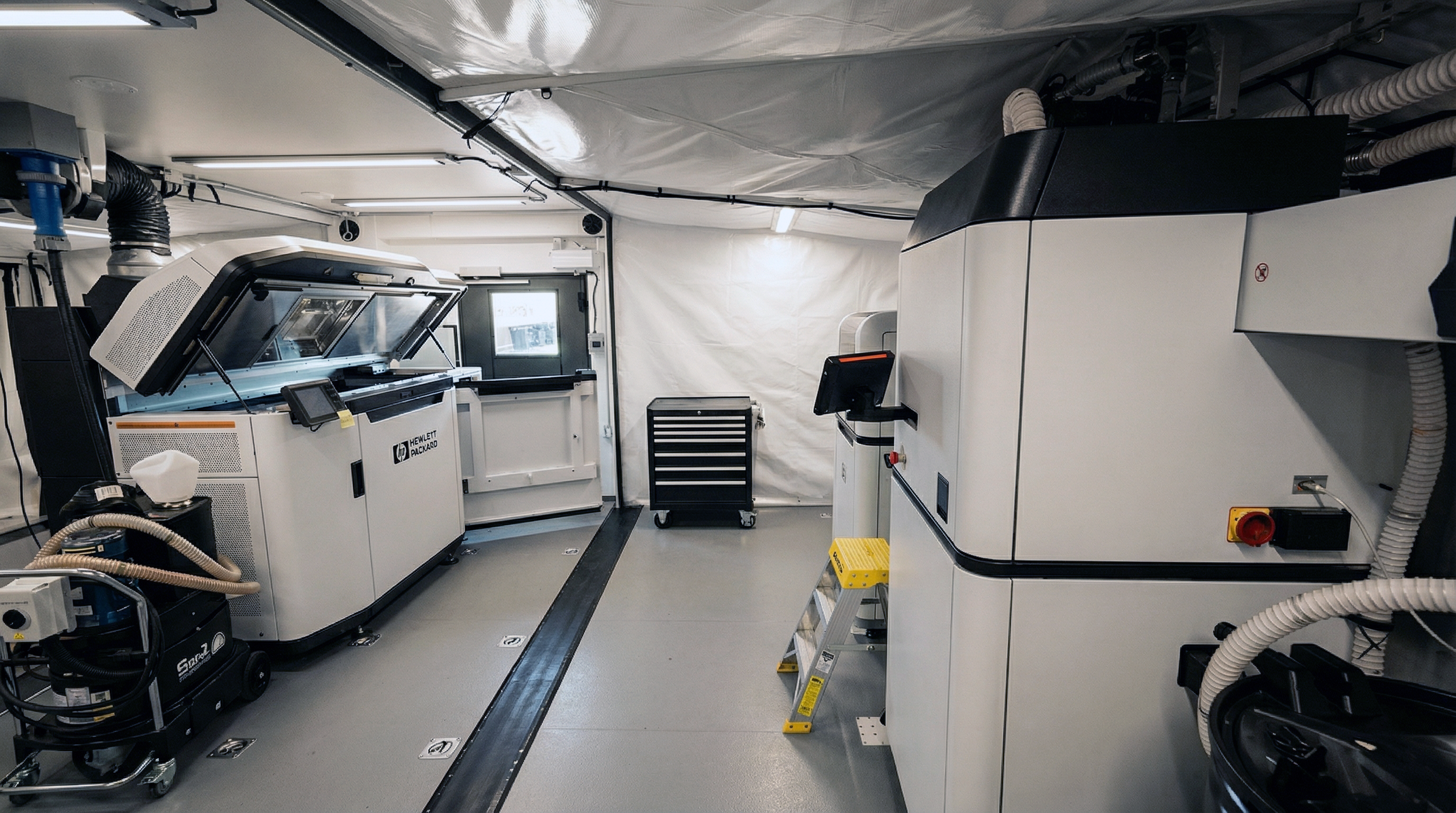

Latest additive manufacturing systems integrated for operational effectiveness

The interior of the delivered MECC facility remains undisclosed, but it incorporates cutting-edge additive manufacturing and 3D printing systems. Installation was performed in strict adherence to manufacturer specifications, ensuring reliability and performance. By integrating these technologies within a redeployable, expandable platform, operators gain unprecedented capacity to design, prototype, and manufacture on demand in forward environments. This innovation means critical spare parts or mission-specific components can be produced immediately, reducing supply chain risk and enhancing resilience.

Showcased products

Showcased solutions

Client feedback

Client Engineer

‘Taking additive manufacturing to the frontline is simply game changing. The MECC really helps project that capability quickly’

US Organisation

Please get in touch if you would like to know more about our Military or Commercial shelter and camp solutions.